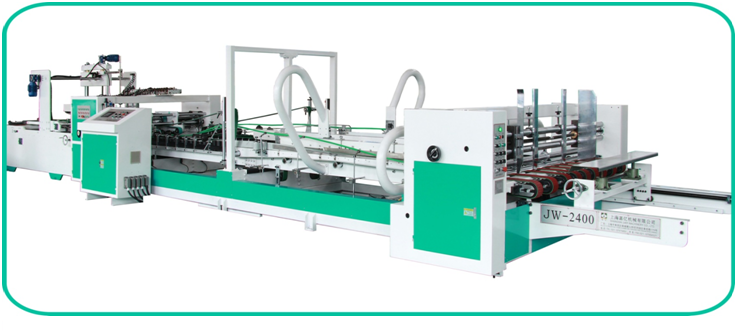

JW series automatic folder gluer machine

JW series automatic folder gluer machine

Mainly applicable for gluing flexo straight-line carton box, standard configuration of JW series automatic folder glue is composed of three parts:feeder section, folding section,t he counter and ejection section.

it is endowed with stable operation and low noise. Up end of the final folding section is equipped with a second line pressing device that can effectively solve the size seam in the process of tapping .

upper belt of the front section of the counter ejection is under step-less speed regulation. In accordance with the continuous tapping of the back-and-forth reciprocating clappers,can effectively reduce formation of the scissors gap in the gluing process.

This machine operate easily, stably, it is the first choice of choosing carton box machine.

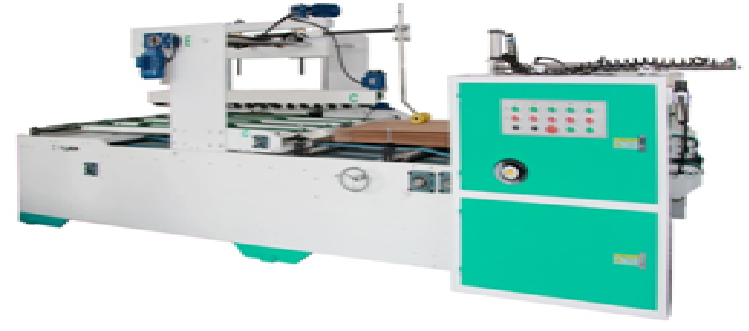

1.Feeder section:

- Cardboard is conveyed through joint work of high friction feeder and high pressure suction.Space of the feeder belt can be adjusted through the tension pulley for cardboard of different width.

2. Baffles are set on both the left and right sides of the feeder section,which can be manually adjusted according to different cardboard’s width.

- Two feeding knives are equipped at the front end of feeder section,which can be adjusted up and down based on different thickness of the cardboard.

4. Step-less speed regulator ensures convenient and quick operation and steady paper feeding.

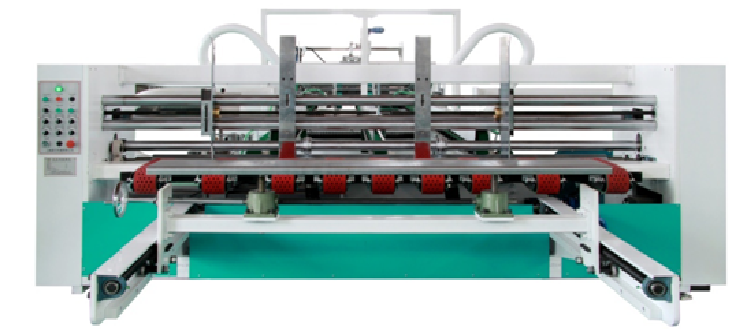

2.Folding Assembly:

- A set of pre-pressing wheels and a glue spreader are set at the front-end of the final folding section,of which the glue spreader is composed of the lower gluing wheel,the upper pinch wheel and the glue case.

- The folding of 180 degrees between the second folding line and the fourth folding line on the left and the right sides of the cardboard is mainly achieved through two 80mm wide turning belts and two folding conductors.The high friction belts in combination with several pinch wheels automatically fold the cardboard to forcefully correct the formed size of the carton ,thus achieving beautiful formation and close tolerance.

- Many idler pulleys at different angels are set in the left and right sides,positions and angles of which can be adjusted according to different characteristics and the thickness of cardboard to make folding more smoothly.

4.Many axial bearings under the bottom belt are installed to support and guide the smooth operation of the belt.

- With the high quality frequency conversion electric motor applied,it achieves flexible speed regulation and low noise

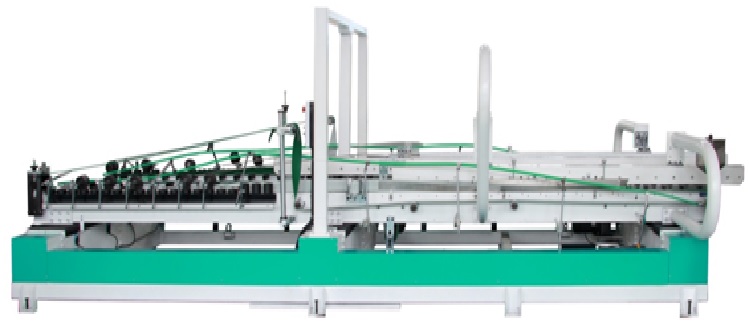

3.Counter and conveyor

1. PLC programmer and touch screen control ensure easily and reliable operation.

2.Input data advance the machine working. Auto detector can output the exact number

3.Adopt Correction regulator, ensure smooth feeding and fall the waster.

4.Counter and the push regulator using pneumatic mode.

4.Technical Date

| Model No | JW-1800 | JW-2400 | JW-2800 | ||||

| Max speed( m/min) | 150 | ||||||

| Corrugated paper | A B C E F Flute. Three、Five-layer Cardboard | ||||||

| Power(kw) | 16 | 17 | 18 | ||||

| Exterior Sizes(m) | 12×2.6×1.6 | 12×3.3×1.8 | 13×3.7×1.8 | ||||

| Weight(tons) | 8.5 | 9 | 9.5 | ||||

| Box-type | Item(mm) | MAX | MIN | MAX | MIN | MAX | MIN |

| A | 1800 | 750 | 2400 | 750 | 2800 | 750 | |

| B | 1000 | 350 | 1200 | 350 | 1200 | 350 | |

| C | 700 | 180 | 1000 | 180 | 1200 | 180 | |