N.C Helical Cut Off XX12

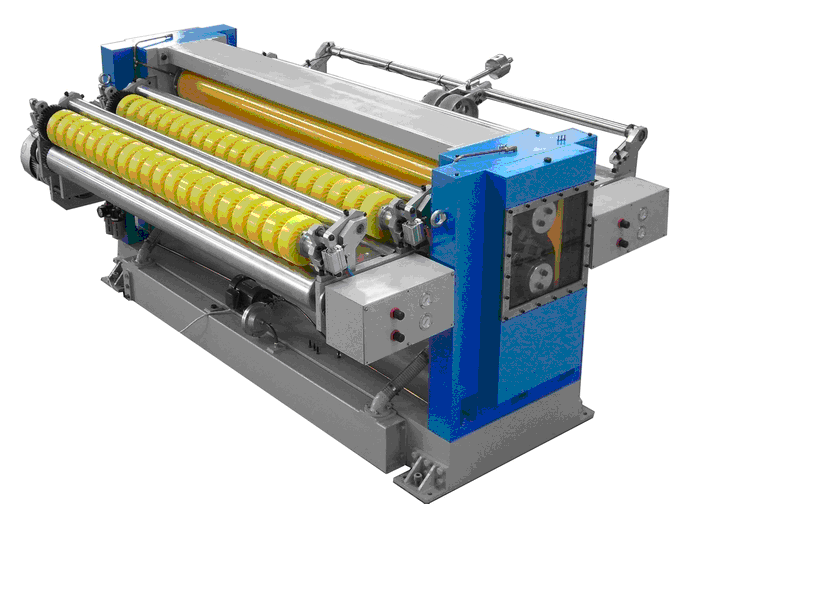

Automatic NC Helical Cutoff (NHC-XX12Series)

The NHC-H series Automatic NC Cutoff is placed between the slitter/scorer and stacker on a corrugated paperboard production line, it cuts the web into blanks according to order request, then feeds out the blanks onto stacker.

Automatic cutting the boards with fixed length. Automatic order change

Automatic tracking of the paperboard speed; automatic synchronization of production speed.

Automatic lubricating of knife shaft and transmission gears

Features:

Special shearing angle of saw-teeth knives create clean cutting surface, the knives don’t touch each other during shearing, and thereof it reduces knife abrasions and power consumption.

Dynamic balanced knife shafts made of special materials, imported bearings and 5th class precise transmission gears lead to high cutting quality and efficiency, low abrasion and power consumption.

Active lubricating system for transmission gears and knife bearings enhance lubricating efficiency at high speed. External lubricating oil tank helps to reduce the working temperature of gears, thus to ensure the stable running condition of equipment in large time scale.

Gear boxes and motor can be removed quickly and easily during maintenance. Advanced design for frame and basement ensures stable production at high speed.

Technical Parameters

| Automatic NC Cutoff NHC-H Series | |

| Model | NHC-XX12X-H |

| Effective width or to client’s request | 1600mm/1800mm/2000mm/2200mm |

| Economic speed | 120 m/min |

| (L*W*H in mm) | 3580x1855x1510 |

| Overall power | 26KW |

| Cutting knife type | helical knife |

| Cut length range | 350mm-9999mm |

| Cutting tolerance at constant speed | ±1mm |

| Cutting tolerance at ac/deceleration | ±1.5mm |

| Orders cache | >1000 |

| Standard power supply | 380V, 50HZ, 3 Phase, 4 Lines |

| Overall weight | about 5 Tons |