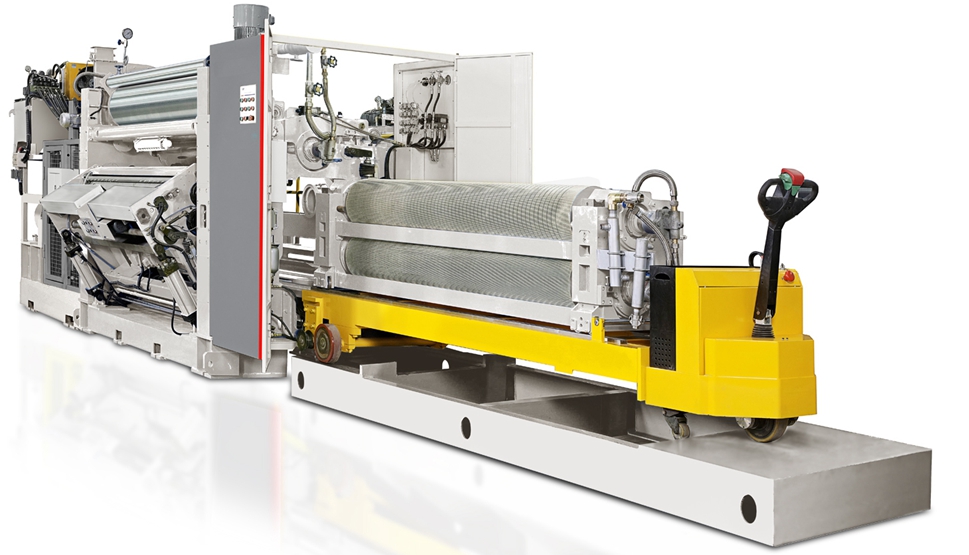

Cassette single facer SFK30

Cassette single facer SFK30

Specification

The negative pressure is given by suction blower and allows for flute shaping;

Circle-sealed casting iron structure of the machine body frame ensures the high strength and less vibration for the machine.

The corrugator rolls are assembled at the lower part of the machine, so the gravity center of the machine is lower. This allows for less vibration and speeds up the changing roll to as quickly as 15 minutes.

Gluing assembling is a trolley type. It is combined with the main machine while working and can be separated from the main machine during maintenance which improves convenience.

Automatic washing system function is set above the glue roll. When the function is selected, the glue roll could be cleaned by sprayed water automatically.

With an enormous database, the machine can adjust the glue application with the gap and pressure of rolls according to the change of the paper quality and running speed, which establishes a smart operation.

Corrugator roll Dia. Top Roll Dia. Φ360mm Bottom roll Dia. Φ360mm

Effective Width 2000mm、2200mm、2500mm

Main Motor Power 37KW (2000mm、2200mm)、45KW(2500mm)

Design speed 250m/min

Heat Source Steam